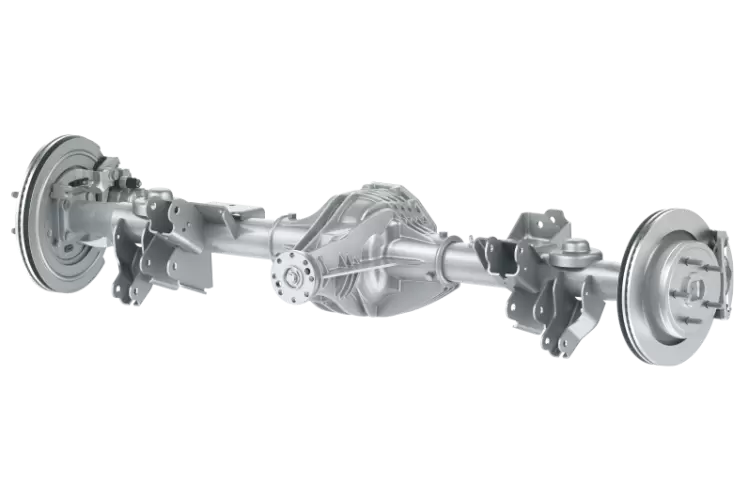

Product Description

Product Description

| Tubing: | 2 3/8″ OD (Standard), Galvanized Option (Marine),Corrosion Resistant Hubs |

| • V-Bend Beam Option | |

| Bolt Pattern Options: | • 5 on 4 1/2″, 4 3/4″, 5″, and 5 1/2″ |

| • 6 on 5 1/2″ | |

| Brake Options: | Some available with parking feature. |

| • 10″ x 2 1/4″ Electric (Manual or Nev-R-Adjust ) | |

| • 10″ x 2 1/4″ Hydraulic (Uni-Servo, Duo-Servo or | |

| Freebacking) | |

| • 10″ X 2 1/4″ Hydraulic Freebacking Corrosion | |

| Resistant (Galv/Marine Axle) | |

| • Hydraulic Disc: 5 on 4 1/2″ only | |

| Spindles: | Uses L68149 Inner Bearing, L44649 Outer Bearing. |

| • Straight • Drop: 4″ or 6″ | |

| • Stainless Steel Wear Sleeves on Galvanized Axles |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | One Year |

|---|---|

| Condition: | New |

| Axle Number: | 2 |

| Application: | Trailer |

| Certification: | ISO |

| Material: | Steel |

| Samples: |

US$ 170/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there potential challenges or limitations to using beam axles in vehicles?

Using beam axles in vehicles has both advantages and disadvantages. It’s important to consider the challenges and limitations associated with beam axles:

1. Ride Quality:

Beam axles are generally stiffer than independent suspension systems. This stiffness can lead to a less comfortable ride on smooth or well-paved roads, as they transmit more road imperfections and vibrations to the passengers. Passengers may perceive this as a limitation in terms of ride comfort.

2. Limited Articulation:

Beam axles have limited articulation. When one wheel encounters a bump or obstacle, the other wheel is affected as well. This can result in a bumpier ride compared to independent suspension systems, where each wheel can move independently to absorb shocks. Off-road vehicles may experience challenges in maintaining traction on rough terrains due to this limitation.

3. Reduced Traction in Some Scenarios:

Beam axles can experience reduced traction in certain scenarios, such as when one wheel loses contact with the ground. In off-road situations, this can limit the vehicle’s ability to traverse uneven terrain, especially when compared to independent suspension systems that allow each wheel to react independently to ground conditions.

4. Challenging Maneuverability:

Maneuverability can be a limitation in vehicles with beam axles. The stiffness and design of beam axles can make it harder to navigate tight spaces or execute sharp turns. This can be a drawback, especially in urban environments or when parking in confined areas.

5. Weight Distribution:

Proper weight distribution is crucial for vehicle stability. Beam axles, while offering even weight distribution between wheels on the same axle, may not provide the same level of precision in weight distribution as independent suspension systems. This can affect handling and stability in some situations.

6. Limited Ride Comfort on Smooth Roads:

On smooth and well-paved roads, solid beam axles may lead to reduced ride comfort due to their stiffness. Passengers may experience a more jarring ride, and the vehicle may struggle to absorb minor road imperfections.

7. Noise and Vibration:

Beam axles can transmit more noise and vibration from the road to the vehicle’s occupants. This can result in a less refined and quieter cabin environment compared to vehicles with independent suspension systems.

8. Suspension Tuning Challenges:

Designing the suspension components and tuning the shock absorbers for vehicles with beam axles can be challenging. Manufacturers must strike a balance between load-carrying capacity and ride comfort. Achieving an ideal balance can be difficult and may require compromises.

9. Vehicle-Specific Considerations:

The limitations of beam axles can vary depending on the vehicle’s intended use and design. While some limitations may be acceptable in off-road or heavy-duty applications, they may not be suitable for passenger cars or vehicles designed for urban commuting.

Summary:

Beam axles offer advantages in terms of durability and load distribution, but they also come with limitations related to ride comfort, maneuverability, and traction in certain scenarios. Vehicle manufacturers must carefully consider these limitations and weigh them against the specific needs and intended use of the vehicle.

Can you describe the maintenance and repair considerations for beam axles?

Maintenance and repair of beam axles, also known as solid axles or live axles, are essential to ensure the longevity and proper functioning of a vehicle. Here are some key maintenance and repair considerations:

Maintenance:

- 1. Lubrication: Regularly inspect and lubricate the axle’s components, such as the bearings, bushings, and kingpins. Proper lubrication helps reduce friction and wear.

- 2. Inspection: Periodically inspect the axle for signs of damage, wear, or corrosion. Check for leaks from the axle’s seals and inspect the axle housing for cracks or dents.

- 3. Tire Alignment: Proper tire alignment is crucial to prevent uneven tire wear and maintain vehicle stability. Ensure that the wheels are aligned correctly to minimize stress on the axle components.

- 4. Wheel Balancing: Imbalanced wheels can cause vibrations and additional stress on the axle. Regularly balance the wheels to prevent premature wear of axle components.

- 5. Tightening Fasteners: Check and tighten fasteners, such as U-bolts and mounting brackets, to ensure they are secure and prevent axle misalignment.

Repair:

- 1. Bearing Replacement: If you notice excessive play, noise, or vibrations in the wheel, it may be a sign of bearing wear. Bearings should be replaced promptly to prevent further damage to the axle.

- 2. Seals and Gaskets: Leaking seals and gaskets should be replaced to prevent oil or grease loss and maintain proper lubrication of axle components.

- 3. Bushings and Kingpins: Worn or damaged bushings and kingpins can affect steering and handling. Replacement may be necessary to restore proper function.

- 4. Axle Straightening: In cases of minor axle damage or bending, some axles can be straightened and repaired. However, severe damage may require axle replacement.

- 5. Welding and Fabrication: In the event of cracks or structural damage to the axle housing, welding and fabrication may be required. This should be performed by a skilled professional to ensure the axle’s integrity.

- 6. Alignment: Proper alignment is critical to prevent uneven tire wear and handling issues. If the axle is misaligned, it should be realigned by a professional technician.

It’s important to note that the complexity of maintenance and repair tasks may vary depending on the type of vehicle and the specific design of the beam axle. Additionally, regular inspections and maintenance can help detect issues early, preventing more extensive and costly repairs in the long run. When performing maintenance and repairs on beam axles, it’s recommended to consult the vehicle’s service manual and seek assistance from qualified mechanics when needed.

Are there different types of beam axles for various vehicle applications?

Yes, there are different types of beam axles designed for various vehicle applications. These variations in beam axles are tailored to meet the specific needs of different types of vehicles and usage scenarios. Here are some of the different types:

1. Front Beam Axles:

Front beam axles are typically used in commercial and heavy-duty trucks, as well as some off-road and industrial vehicles. They are designed to provide robust load-bearing capabilities and stability for front-wheel drive vehicles, especially those used in construction, mining, and transportation of heavy loads.

2. Rear Beam Axles:

Rear beam axles are commonly used in various vehicle types, including trucks, vans, and off-road vehicles. They offer load-carrying capacity and are suitable for applications where traction and durability are important. In trucks, the rear beam axle often supports the weight of the cargo.

3. Off-Road Beam Axles:

Off-road vehicles, such as 4×4 trucks and SUVs, use specialized beam axles designed for rugged terrain. These beam axles provide increased articulation and durability, allowing the vehicle to maintain traction and control in challenging off-road conditions.

4. Independent Beam Axles:

Some vehicles, particularly in the realm of all-terrain and recreational vehicles, feature independent beam axles. These axles combine the strength of beam axles with the ability to articulate independently, offering a compromise between load-bearing capacity and off-road performance.

5. Solid and Tube Beam Axles:

Beam axles can come in different designs, including solid and tube axles. Solid beam axles consist of a single, solid shaft, while tube axles are hollow, reducing weight while maintaining strength. The choice depends on the vehicle’s requirements.

6. Retro and Classic Beam Axles:

In the context of classic and retro vehicles, beam axles are sometimes retained for authenticity. Modern vehicles with retro styling may incorporate beam axles to capture the aesthetics and character of older vehicle designs.

7. Tandem Beam Axles:

In heavy-duty trucks and trailers, tandem beam axles are often used. These axles are arranged in tandem pairs to distribute the load more evenly and improve load-bearing capacity, making them suitable for long-haul transportation.

The choice of beam axle type depends on the intended use, vehicle design, and the specific demands of the application. Manufacturers select the appropriate beam axle configuration to optimize vehicle performance, load-carrying capacity, and durability for a given scenario.

editor by CX 2024-04-17

China Good quality Hydraulic Ladder Axles with Concave Beam Lowbed Semi Trailer broken axle cost

Product Description

With concave beam hydraulic ladder axles lowbed semi trailer

Product Description

| Product Information | |||||

| Product | Low bed semi trailer | ||||

| Brand Name | CHHGC Brand | ||||

| Model Number | ZJV9191TD | ||||

| OEM | available | ||||

| Place of Origin | ZheJiang province, China | ||||

| Color | Any color will be available | ||||

| Manufacturer | ZheJiang CZPT Import and export Co.,Ltd. | ||||

| Product Specifications | |||||

| Parameter | |||||

| Outside Dimensions (L*W*H) | L:12000-20000 W:2400-4000 H:900-1500 | ||||

| Rated Load | 30ton-500ton | ||||

| Tare Weight | More than 9000kgs | ||||

| Wheel Base | 8480+1310 (mm) | ||||

| Running Gear | |||||

| Tires | specification | 12R22.5 ,11.00R20 or depends on customer | |||

| No. of tires | 8,12,16 or more than 20 | ||||

| Spare tire carriers | 2 or 1 including a riser. | ||||

| Axles |

Brand : | FUWA (BPW German optional) | |||

| No. of axles: | 2,3 4 or more than 5 | ||||

| Axle-load | 13000kgs | ||||

| Wheel rim | 8units of 7.50-20 rim or 8.00 | ||||

| Suspension | Rigid suspension and air suspension | ||||

| Pieces of leaf-spring | 10/10/10 | ||||

| Brakes | brand | TKL brand | |||

| Brake chamber | 4 double chamber | ||||

| System | Dual line braking system /ABS | ||||

| Under Frame | |||||

| Departure Angle | 14 | ||||

| Front/Rear Overhang | 1670mm | ||||

| Main Beam | material | I beam ,Q345B , automatic submerged arc welded | |||

| specification | Height is 500mm,upper plate is 20mm,lower plate is 20mm,middle is 12mm |

||||

| Cross Beam material | Q235B | ||||

| Side beam | 16# channel steel | ||||

| Plate form | Steel Sheet 5mm thickness or CZPT plate(Also can choose other thickness ,such as 2mm,2.5mm,3mm,4mm,5mm,6mm) |

||||

| King Pin | 50# or 90# | ||||

| Landing gear | Single side operation or double side operation, Static capacity 28Ton | ||||

| Accessory | One tooling box with a set of standard trailer tool | ||||

| Electrical | |||||

| Voltage | 24V | ||||

| Receptacle | 7 ways (7 wire harness) | ||||

| Lights | Front corner marker lamp :red ;reflector lamp :white | ||||

| Side marker :orange | |||||

| Rear lamp :red; rear reflector :white; turn single lamp :orange | |||||

| Other | |||||

| Usage | The height of the cargo’s carrying platform is 800-1290mm, is suitable For the transportation of the large and non-dismantled objects. |

||||

| Other Specifications | The max height of the rear guard from ground is 420mm | ||||

| Other Descriptions | The whole body adopts steel with good quality, and be manufactured by advanced skills and strict producing managerial processes. The frame is wearing structure, webs made from manganese plates from 400mm to 550mm high welded the upper and lower flange plates together, and the beam runs through the longitudinal beam makes the 2 parts a very strong unit by automatic submerged arc welding. Frame using peen-forming processing. |

||||

| Painting ,marking and side guard can according to the customer’s requirement. | |||||

Certificate

Workshop

Business Partners

FAQ:

Q1. How to ship the vehicles?

A: By container, bulk ship, RORO.

Q2. Do you have RHD(right hand driving) vehicles?

A: Yes, noramlly we supply all LHD vehicles, and we have some RHD model vehicles.

Q3. What is your payment term?

A: We usually accept T/T or L/C depends on the quantity.

T/T, deposit in advance, and balance paid before delivery from factory.

Q4. Which model vehicles do you supply?

A: We supply all kinds of vehicles such as SUV, MPV, Pickup,van,truck, bus etc,.

Q5. What is your terms of delivery?

A: FOB, CIF.

Q6. How about your delivery time?

A: Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: What can you guarantee to your business partner?

A: Best price with good quality. We guarantee quality and after sale service to satisfy our business partners. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Load Capacity: | 30ton-500ton |

|---|---|

| Certification: | ECE, GCC, CE, ISO9001 |

| Wheel Base: | 8580+1310+1310 |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the considerations for off-road vehicles using beam axles?

Off-road vehicles that use beam axles have specific considerations to optimize performance and durability in challenging terrain. Here are the key factors to keep in mind when designing or using off-road vehicles with beam axles:

1. Ground Clearance:

Off-road vehicles require sufficient ground clearance to navigate over rocks, ruts, and uneven terrain. Beam axles, with their ability to provide good ground clearance, are a practical choice for these applications. Vehicle designers may also opt for suspension lifts to further increase ground clearance.

2. Wheel Articulation:

Off-roading often involves traversing uneven surfaces where individual wheel movement is essential to maintain traction and stability. Beam axles offer excellent wheel articulation, allowing each wheel to move independently and adapt to the terrain, keeping the tires in contact with the ground. This enhances the vehicle’s ability to overcome obstacles and maintain grip on challenging trails.

3. Durability and Impact Resistance:

Off-road environments can subject a vehicle to rough conditions and potential impacts from rocks, tree roots, and other obstacles. Beam axles are designed to be durable and resistant to damage. The choice of materials and construction should prioritize strength and impact resistance to ensure the axles can withstand the rigors of off-roading.

4. Suspension Tuning:

Off-road vehicles often require suspension tuning to achieve optimal performance. This includes selecting appropriate shock absorbers, springs, and other components to balance ride comfort and off-road capability. Tuning the suspension can improve handling, reduce body roll, and enhance overall off-road performance.

5. Differential Locking:

Off-road vehicles may benefit from differential locking mechanisms that ensure power is evenly distributed between the wheels on an axle. This helps prevent wheel spin and ensures that both wheels receive power for maximum traction. Locking differentials can be a valuable addition to vehicles with beam axles.

6. Tire Selection:

The choice of off-road tires is crucial. Tires with deep treads and appropriate tread patterns are essential for traction in mud, sand, and rocks. Tire pressure can also be adjusted to suit the terrain, and beadlock wheels can help secure the tires in challenging conditions.

7. Regular Maintenance:

Off-road vehicles with beam axles should undergo regular maintenance to ensure they remain in top condition. This includes inspecting and lubricating the axles, checking for signs of wear or damage, and addressing any issues promptly to prevent breakdowns during off-road adventures.

8. Customization:

Off-road enthusiasts often customize their vehicles with features like winches, skid plates, and roll cages to enhance off-road capabilities and safety. These modifications should be integrated with the beam axle suspension to ensure compatibility and functionality.

Summary:

Off-road vehicles using beam axles require careful consideration of ground clearance, wheel articulation, durability, and various other factors to optimize their performance in challenging terrains. Proper suspension tuning, tire selection, and maintenance are essential to ensure a safe and enjoyable off-roading experience.

Can you describe the maintenance and repair considerations for beam axles?

Maintenance and repair of beam axles, also known as solid axles or live axles, are essential to ensure the longevity and proper functioning of a vehicle. Here are some key maintenance and repair considerations:

Maintenance:

- 1. Lubrication: Regularly inspect and lubricate the axle’s components, such as the bearings, bushings, and kingpins. Proper lubrication helps reduce friction and wear.

- 2. Inspection: Periodically inspect the axle for signs of damage, wear, or corrosion. Check for leaks from the axle’s seals and inspect the axle housing for cracks or dents.

- 3. Tire Alignment: Proper tire alignment is crucial to prevent uneven tire wear and maintain vehicle stability. Ensure that the wheels are aligned correctly to minimize stress on the axle components.

- 4. Wheel Balancing: Imbalanced wheels can cause vibrations and additional stress on the axle. Regularly balance the wheels to prevent premature wear of axle components.

- 5. Tightening Fasteners: Check and tighten fasteners, such as U-bolts and mounting brackets, to ensure they are secure and prevent axle misalignment.

Repair:

- 1. Bearing Replacement: If you notice excessive play, noise, or vibrations in the wheel, it may be a sign of bearing wear. Bearings should be replaced promptly to prevent further damage to the axle.

- 2. Seals and Gaskets: Leaking seals and gaskets should be replaced to prevent oil or grease loss and maintain proper lubrication of axle components.

- 3. Bushings and Kingpins: Worn or damaged bushings and kingpins can affect steering and handling. Replacement may be necessary to restore proper function.

- 4. Axle Straightening: In cases of minor axle damage or bending, some axles can be straightened and repaired. However, severe damage may require axle replacement.

- 5. Welding and Fabrication: In the event of cracks or structural damage to the axle housing, welding and fabrication may be required. This should be performed by a skilled professional to ensure the axle’s integrity.

- 6. Alignment: Proper alignment is critical to prevent uneven tire wear and handling issues. If the axle is misaligned, it should be realigned by a professional technician.

It’s important to note that the complexity of maintenance and repair tasks may vary depending on the type of vehicle and the specific design of the beam axle. Additionally, regular inspections and maintenance can help detect issues early, preventing more extensive and costly repairs in the long run. When performing maintenance and repairs on beam axles, it’s recommended to consult the vehicle’s service manual and seek assistance from qualified mechanics when needed.

Can you explain the role of a beam axle in a vehicle’s stability and handling?

A beam axle, also known as a solid axle or live axle, plays a significant role in a vehicle’s stability and handling, albeit with some trade-offs compared to independent suspension systems. Here’s an explanation of its role:

Stability:

- 1. Load Distribution: Beam axles contribute to even load distribution between the two wheels on the same axle. This helps maintain stability, especially when the vehicle is carrying heavy loads or towing trailers. It prevents one wheel from becoming excessively loaded, which can lead to uneven tire wear and instability.

- 2. Support for Heavy Loads: In applications that require carrying substantial weight, such as commercial trucks and heavy-duty vehicles, beam axles provide the necessary structural support. This ensures that the vehicle remains stable and can handle the load safely.

- 3. Rugged Terrain: In off-road and 4×4 vehicles, the solid construction of beam axles helps maintain stability and control on rough and uneven terrain. The axle’s ability to flex and maintain contact with the ground is crucial for off-road performance.

Handling:

- 1. Simplified Handling: Beam axles provide simplified handling characteristics. When both wheels on the same axle move together, it can result in predictable and straightforward handling, making them suitable for certain applications.

- 2. Improved Traction (Off-Road): In off-road vehicles, the ability of both wheels on a beam axle to move in unison enhances traction. When one wheel loses grip, the other compensates by maintaining contact with the terrain, increasing off-road capabilities.

- 3. Predictable Response: Vehicles with beam axles tend to provide a predictable response to steering inputs and road conditions, which can be an advantage in specific scenarios.

Limitations: While beam axles offer stability and simplified handling, they come with some limitations that can affect overall vehicle dynamics:

- 1. Reduced Comfort: On uneven road surfaces, the simultaneous movement of both wheels on a beam axle can result in a less comfortable ride due to the transmission of bumps and imperfections directly to the vehicle’s cabin.

- 2. Limited Handling Precision: Beam axles may result in less precise handling, especially in high-speed or cornering situations. The interconnected movement of wheels can lead to less agility and stability in such scenarios.

- 3. Reduced Adaptability: The handling characteristics of vehicles with beam axles are less adaptable to a wide range of road conditions compared to vehicles with independent suspension, which can adjust each wheel independently to changing terrain.

In summary, the role of a beam axle in a vehicle’s stability and handling is to provide even load distribution, support heavy loads, and maintain control in specific situations. However, this comes at the cost of reduced ride comfort and handling precision, making beam axles more suitable for certain applications, such as heavy-duty trucks, off-road vehicles, and scenarios where simplicity and load-carrying capacity are prioritized over comfort and precision.

editor by CX 2024-04-10

China Professional Hydraulic Ladder 3axles Heavy Duty 60ton 80tons Low Bed Semi Trailers Lowbed Trailer Lowboy Axle for Sale axle cap

Product Description

Product Description

Hydraulic Ladder 3axles Heavy Duty 60ton 80tons Low Bed Semi Trailers Lowbed Trailer Lowboy Axle for Sale

Lowbed semi-trailers are usually used to transport heavy vehicles (such as tractors buses special vehicles etc.) rail vehicles mining machinery forestry machinery construction machinery (such as excavators bulldozers loaders paving machines cranes etc.) And other heavy-loaded goods the lower the center of gravity the better the stability and safety and the stronger the ability to transport ultra-high goods and pass overhead obstacles.

The 3 axle lowbed semi trailer is specially designed for heavy transportation. It has many advantages, high safety and stability, and our 3 axle lowbed semi trailer is more stable than other types of semi trailer. It can carry hundreds of tons of weight. Lowboy trailer is an ideal choice for transporting heavy objects. Because of its solid structure, it can withstand a lot of pressure during transportation. Many heavy machines are too heavy and bulky to be moved by normal transportation vehicles, and 3 axle lowbed semi trailer can easily transport them. And because the chassis is low, it can pass under the obstacles above.

The 3 axle lowbed semi trailer is specially designed for heavy transportation. It has many advantages, high safety and stability, and our 3 axle lowbed semi trailer is more stable than other types of semi trailer. It can carry hundreds of tons of weight. Lowboy trailer is an ideal choice for transporting heavy objects. Because of its solid structure, it can withstand a lot of pressure during transportation. Many heavy machines are too heavy and bulky to be moved by normal transportation vehicles, and 3 axle lowbed semi trailer can easily transport them. And because the chassis is low, it can pass under the obstacles above.

Product Parameters

| DIMENSIONS | |||||||||||||

| Tare weight | 10000kg | Payload | 60000kg | ||||||||||

| Overall length | 13000mm | Overall width | 3000mm | Overall height | 1750mm | ||||||||

| SPECIFICATION | |||||||||||||

| Chassis | Heavy duty and extra durability designed I beam; opting for high tensile Q345, welded by automatic submerged-Arc processes. Top plate 20mm, bottom plate 20mm, middle plate 14mm, height 500mm | ||||||||||||

| Axle | Number | 3 | Brand | Optional upon choice | Capacity | 13T | |||||||

| Suspension | Mechanical suspension or air suspension | ||||||||||||

| Leaf spring | Leaf spring or air bag | ||||||||||||

| Floor | Checkered plate | ||||||||||||

| Tire | 11.00R20, 12.00R20, 11R22.5, 12R22.5, 315/80R22.5 Tire optional | ||||||||||||

| Wheel rim | 8.5-20, 9.0-20, 8.25-22.5, 9.0-22.5 steel wheel rim optional upon choice | ||||||||||||

| Kingpin | 2”/3.5” bolt-in king pin | ||||||||||||

| Landing gear | JOST brand two-speed, manual operating, heavy duty landing gear | ||||||||||||

| Ladder | Mechanical ladder | ||||||||||||

| Vehicular applications | Machine transport | ||||||||||||

| Braking system | WABCO RE6 relay valve; T30/30 spring brake chamber; 40L air tanks | ||||||||||||

| Painting | Complete chassis sand blasting to clean rust, 1 coat of anti-corrosive prime, 2 coat of final paint | ||||||||||||

| Accessories | One standard tool box | ||||||||||||

Packaging & Shipping

Company Profile

ZheJiang Maxway Vehicle Co. Ltd.. started truck semi trailer business in 2007, factory is located in Xihu (West Lake) Dis. town, ZheJiang province.

As a reliable manufacturer with vitality, potential and comprehensive strength, Maxway vehicle mainly provides bulk cement tank trailer, low bed trailer, extendable semi trailer,detachable gooseneck trailer, fuel oil tank semi trailer, biHangZhou tank trailer, LPG/LNG/CNG tank trailer, flatbed container trailer, skeleton trailer, stake box/cargo/fence trailer, dump and tipping trailer, car carrier semi trailer, wood/timber transportation trailer and trailer parts. Also we have professional desinging team for your customized requirements.

After Sales Service

– Providing high quality and reliability products, free of charge during the warranty period for spare parts.

– 24 hours corresponding your feedback.

– Technicians fully supports on technology and maintenance.

– With a variety of trailer accessories and delivery within 3 days.

– Perfect and economic transportation arrangement.

Quality Guarantee

– All spare parts are from famous brand or your Customized.

– All spare parts are testing before assembly.

– High quality automatic and manual welding.

– Quality control supervisor do inspection before delivery.

– Acceptance for third party inspection.

FAQ

Q1. What is your terms of packing?

A: Generally, our goods is nude packing. We’ll show you the photos of the products and packages before delivery.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% the balance before delivery.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF..

Q4. How about your delivery time?

A: Generally,it will take 15 to 30 working days after received your deposit.Also depends on the items and the quantity of your order.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% testing before delivery

Q6: How do you make our business long-term and good relationship?

1. With high quality products and competitive price;

2. We respect each customer and sincerely do business, CZPT Cooperation.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Overseas After Sales Service |

|---|---|

| Warranty: | 12 Months |

| Type: | Semi-Trailer |

| Load Capacity: | 50T |

| Certification: | ISO9001, CCC |

| Wheel Base: | 7000-8000mm |

| Customization: |

Available

| Customized Request |

|---|

Can you provide insights into the maintenance of axle bearings for smooth operation?

Maintaining axle bearings is essential for ensuring smooth operation, longevity, and optimal performance of a vehicle’s axle system. Here are some insights into the maintenance of axle bearings:

1. Regular Inspection:

Perform regular visual inspections of the axle bearings to check for any signs of wear, damage, or leaks. Look for indications such as excessive play, unusual noises, vibration, or leakage of grease. Inspections should be carried out as per the manufacturer’s recommended intervals or during routine maintenance checks.

2. Lubrication:

Adequate lubrication is crucial for the smooth operation of axle bearings. Follow the manufacturer’s guidelines for the type of lubricant to use and the recommended intervals for greasing. Over-greasing or under-greasing can lead to bearing damage or failure. Ensure that the proper amount of grease is applied to the bearings, and use a high-quality grease that is compatible with the axle bearing specifications.

3. Seal Inspection and Replacement:

Check the condition of the axle bearing seals regularly. The seals help to keep contaminants out and retain the lubricating grease within the bearing. If the seals are damaged, worn, or show signs of leakage, they should be replaced promptly to prevent dirt, water, or debris from entering the bearing assembly and causing damage.

4. Proper Installation:

During axle bearing replacement or installation, it is crucial to follow proper procedures to ensure correct seating and alignment. Improper installation can lead to premature bearing failure and other issues. Refer to the manufacturer’s instructions or consult a professional mechanic to ensure proper installation techniques are followed.

5. Load Capacity and Alignment:

Ensure that the axle bearings are properly sized and rated to handle the load capacity of the vehicle and the specific application. Overloading the bearings can lead to excessive wear and premature failure. Additionally, proper wheel alignment is important to prevent uneven bearing wear. Regularly check and adjust the wheel alignment if necessary.

6. Environmental Considerations:

Take into account the operating conditions and environment in which the vehicle is used. Extreme temperatures, exposure to water, dirt, or corrosive substances can affect the performance of axle bearings. In such cases, additional preventive measures may be necessary, such as more frequent inspections, cleaning, and lubrication.

7. Professional Maintenance:

If you are unsure about performing maintenance on axle bearings yourself or if you encounter complex issues, it is recommended to seek assistance from a qualified mechanic or technician who has experience with axle systems. They can provide expert advice, perform necessary repairs or replacements, and ensure proper maintenance of the axle bearings.

By following these maintenance insights, you can help ensure the smooth operation, longevity, and reliability of axle bearings, contributing to the overall performance and safety of the vehicle.

Can you provide insights into the advancements in axle technology in recent years?

In recent years, there have been significant advancements in axle technology to enhance performance, efficiency, and safety in vehicles. Here are some insights into the key advancements:

- Lightweight Materials:

- Electronic Differential:

- Advanced Axle Bearings:

- Electric Axles:

- Active Suspension Integration:

- Improved Sealing and Lubrication:

- Autonomous Vehicle Integration:

One notable advancement is the use of lightweight materials in axle construction. Manufacturers have increasingly utilized materials such as aluminum alloys and high-strength steels to reduce the weight of axles without compromising strength and durability. Lighter axles contribute to improved fuel efficiency and overall vehicle performance.

Electronic differentials, also known as eDiffs, have gained popularity in recent years. They utilize sensors, actuators, and control algorithms to monitor and distribute torque between the wheels more efficiently. Electronic differentials enhance traction, stability, and handling by actively managing torque distribution, especially in vehicles equipped with advanced stability control systems.

Axle bearings have seen advancements in design and materials to reduce friction, improve efficiency, and enhance durability. For example, the use of roller bearings or tapered roller bearings has become more prevalent, offering reduced frictional losses and improved load-carrying capacity. Some manufacturers have also introduced sealed or maintenance-free bearings to minimize maintenance requirements.

With the rise of electric vehicles (EVs) and hybrid vehicles, electric axles have emerged as a significant technological advancement. Electric axles integrate electric motors, power electronics, and gear systems into the axle assembly. They eliminate the need for traditional drivetrain components, simplify vehicle packaging, and offer benefits such as instant torque, regenerative braking, and improved energy efficiency.

Advancements in axle technology have facilitated the integration of active suspension systems into axle designs. Active suspension systems use sensors, actuators, and control algorithms to adjust the suspension characteristics in real-time, providing improved ride comfort, handling, and stability. Axles with integrated active suspension components offer more precise control over vehicle dynamics.

Axles have seen advancements in sealing and lubrication technologies to enhance durability and minimize maintenance requirements. Improved sealing systems help prevent contamination and retain lubricants, reducing the risk of premature wear or damage. Enhanced lubrication systems with better heat dissipation and reduced frictional losses contribute to improved efficiency and longevity.

The development of autonomous vehicles has spurred advancements in axle technology. Axles are being designed to accommodate the integration of sensors, actuators, and communication systems necessary for autonomous driving. These advancements enable seamless integration with advanced driver-assistance systems (ADAS) and autonomous driving features, ensuring optimal performance and safety.

It’s important to note that the specific advancements in axle technology can vary across different vehicle manufacturers and models. Furthermore, ongoing research and development efforts continue to drive further innovations in axle design, materials, and functionalities.

For the most up-to-date and detailed information on axle technology advancements, it is advisable to consult automotive manufacturers, industry publications, and reputable sources specializing in automotive technology.

Can you explain the importance of axle alignment for vehicle stability and handling?

Axle alignment plays a crucial role in ensuring vehicle stability and handling characteristics. Proper alignment of the axles is essential for maintaining optimal tire contact with the road surface, minimizing tire wear, maximizing traction, and promoting safe and predictable handling. Here are the key reasons why axle alignment is important:

- Tire Wear and Longevity:

- Optimal Traction:

- Steering Response and Stability:

- Reduced Rolling Resistance:

- Vehicle Safety:

Correct axle alignment helps distribute the vehicle’s weight evenly across all four tires. When the axles are properly aligned, the tires wear evenly, reducing the risk of premature tire wear and extending their lifespan. Misaligned axles can cause uneven tire wear patterns, such as excessive wear on the inner or outer edges of the tires, leading to the need for premature tire replacement.

Proper axle alignment ensures that the tires maintain optimal contact with the road surface. When the axles are aligned correctly, the tires can evenly distribute the driving forces, maximizing traction and grip. This is particularly important during acceleration, braking, and cornering, as proper alignment helps prevent tire slippage and improves overall vehicle stability.

Axle alignment directly affects steering response and stability. When the axles are properly aligned, the vehicle responds predictably to driver inputs, providing precise and accurate steering control. Misaligned axles can lead to steering inconsistencies, such as pulling to one side or requiring constant correction, compromising vehicle stability and handling.

Proper axle alignment helps reduce rolling resistance, which is the force required to move the vehicle forward. When the axles are aligned correctly, the tires roll smoothly and effortlessly, minimizing energy loss due to friction. This can contribute to improved fuel efficiency and reduced operating costs.

Correct axle alignment is crucial for ensuring vehicle safety. Misaligned axles can affect the vehicle’s stability, especially during emergency maneuvers or sudden lane changes. Proper alignment helps maintain the intended handling characteristics of the vehicle, reducing the risk of loss of control and improving overall safety.

To achieve proper axle alignment, several key parameters are considered, including camber, toe, and caster angles. Camber refers to the vertical tilt of the wheel when viewed from the front, toe refers to the angle of the wheels in relation to each other when viewed from above, and caster refers to the angle of the steering axis in relation to vertical when viewed from the side. These alignment angles are adjusted to meet the vehicle manufacturer’s specifications and ensure optimal performance.

It’s important to note that factors such as road conditions, driving habits, and vehicle modifications can affect axle alignment over time. Regular maintenance and periodic alignment checks are recommended to ensure that the axles remain properly aligned, promoting vehicle stability, handling, and safety.

editor by CX 2024-04-09

China high quality Hydraulic Extendable 3 Axle 60ton Gooseneck Low Boy Low Bed Trailer 100 Ton Lowboy Semi Trailer with Best Sales

Product Description

Low Bed Semi Trailer, as known as low bed trailer, lowbed trailer, lowboy trailerOur lowbed trailer choose Q345B carbon high-10sile steel material. We adoptworld famous brand of parts, like JOST, CZPT braking valve etc.

The product complies with international standards such as lMDG /ADR /RIDITC/CSC/ ASME / EN, and is applicable to the global shipping, road and railtransportation regulations and standards.

Our Advantages

Why Choose Us

Factory Direct, No Middle Man, No Agency Fees, Therefore Low Price For High Quality Only From Us. Directly Manufactured From Our Own Factory, Can Be Customized For Various Needs Cutting Edge Automation Equipment Adopted In The Factory, Improved Quality From Traditional Production Methods Light Weight Of The Whole Vehicle, Guaranteed Anti Distortion, Anti-seismic And Anti Bumping Steel Welded By Automatic Submerged Arc Process, Connection Spots Look Flawless, More Solid And Durable Compared With Traditional Manual Ways. Cover Painting Is More Sustainable, Corrosion-resistant, Uniform And Smooth, Using Sand Blasting Powder Painting Process

Product Description

Detailed Photos

Product Parameters

|

4 line 8 axles LOWBED SEMI TRAILER |

|

|

Model Number |

WHLDM-1015008 |

|

Outside Dimensions |

13500x2500x1500 (mm) (LxWxH) (Other Dimension Optional) |

|

Rated Load |

90-120T |

|

Tare Weight |

9900 kg |

|

Usage |

For heavy duty machine, as transformer, crane, excavator transportation. |

|

Wheel Base |

8310+13101310 (mm) |

|

Axle Brand |

13t X CZPT Brand |

|

No. Of the Axles |

8 |

|

Tyre Specifications |

10.00R20 |

|

No. Of the Tyres |

32 pcs , Triangle brand |

|

Pieces of leaf-spring |

10pcs *90 *16mm |

|

Suspension |

Heavy Duty Leaf Spring |

|

Front/Rear Overhang |

1950 mm |

|

Floor |

3mm management plate |

|

Tool Box |

1 box of standard tools |

|

Spare tire carrier |

2 sets |

|

Main Beam Material |

Q345B/ST52-3 manganese plates, automatic submerged arc, |

|

Main-beam Height 500mm, |

|

|

Lower flange: 20mm |

|

|

Upper flange: 20mm |

|

|

Mid Web: 12mm |

|

|

Brake Air Chamber |

Four double and 2 single chamber |

|

The traction pin |

2′ & 3.5′ inter-changeable |

|

Pin Height |

According to the height of the tractor saddle. |

|

Electrical System |

24V, 7core socket, lights according to European standards. |

|

Brake System |

Dual Lines Braking System With Automatic Air Chambers |

|

Color and Logo |

Depends on the buyer’s requirement. |

|

Place of Origin |

Xihu (West Lake) Dis., China |

Company Profile

Xihu (West Lake) Dis. Xinrun Trading Co., Ltd. is an integrated enterprise of industry and trade, established in 2571, located in Xihu (West Lake) Dis. County, HangZhou City, ZheJiang Province. The company is mainly engaged in the import and export of trailer accessories such as trailers, semi-trailers, dump trailers, axles, chemical equipment, and other goods, automobile sales, retail of automobile parts, second-hand car brokerage, mechanical equipment sales, and metal material sales; Selling construction machinery and retail hardware products; Special equipment sales; Wholesale of hardware products; Motor vehicle repair and maintenance; Tire sales; Sales of pharmaceutical specific equipment. The company values professionalism, integrity, and trustworthiness as its core values. Looking forward to cooperating with you!

Production Process

Packaging & Shipping

FAQ

Q1: Does your company is a factory or trade company?

A1: We have a factory ourself,we are on this business for few years in China. Our factory is very famous in the ZheJiang China.

Q2: Whats the qualify assurance we provided and how do we control quality?

A2: Established a procedure to check products at all stages of the manufacturing process-raw materials,process materials,validated or tested materials finished goods ect. Beside,we have also developed a procedure which identifies the inspection and test status of all items at all stages of the manufacturing process. 100% inspection in assembly lines. All controls, inspections,equipment,fixtures,total production resources and skills are inspected to ensure they consistently achieve the required quality levels.

Q3: What’s your MOQ?

A3: One unit trailer or truck.

Q4: How do you transport the semi trailers ?

A4: We transport the vehicle by bulk or container. Our factory possess long -term cooperation with ship agency which can provide you lowest shipping fee.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | One Years |

|---|---|

| Warranty: | One Years |

| Type: | Semi-Trailer |

| Load Capacity: | 50T |

| Certification: | ISO9001, CCC, ISO/TS16949 |

| Wheel Base: | 8000-9000mm |

| Samples: |

US$ 5800/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What is the role of axles in electric vehicles, and how do they differ from traditional axles?

Electric vehicles (EVs) have unique requirements when it comes to their drivetrain systems, including the axles. The role of axles in EVs is similar to traditional vehicles, but there are some key differences. Here’s a detailed explanation of the role of axles in electric vehicles and how they differ from traditional axles:

Role of Axles in Electric Vehicles:

The primary role of axles in electric vehicles is to transmit torque from the electric motor(s) to the wheels, enabling vehicle propulsion. The axles connect the motor(s) to the wheels and provide support for the weight of the vehicle. Axles are responsible for transferring the rotational force generated by the electric motor(s) to the wheels, allowing the vehicle to move forward or backward.

In electric vehicles, the axles are an integral part of the drivetrain system, which typically includes an electric motor(s), power electronics, and a battery pack. The axles play a crucial role in ensuring efficient power transfer and delivering the desired performance and handling characteristics of the vehicle.

Differences from Traditional Axles:

While the fundamental role of axles in electric vehicles is the same as in traditional vehicles, there are some notable differences due to the unique characteristics of electric propulsion systems:

1. Integration with Electric Motors: In electric vehicles, the axles are often integrated with the electric motors. This means that the motor(s) and axle assembly are combined into a single unit, commonly referred to as an “electric axle” or “e-axle.” This integration helps reduce the overall size and weight of the drivetrain system and simplifies installation in the vehicle.

2. High Torque Requirements: Electric motors generate high amounts of torque from the moment they start, providing instant acceleration. As a result, axles in electric vehicles need to handle higher torque loads compared to traditional axles. They are designed to withstand the torque output of the electric motor(s) and efficiently transmit it to the wheels.

3. Regenerative Braking: Electric vehicles often utilize regenerative braking, which converts the vehicle’s kinetic energy into electrical energy and stores it in the battery. The axles in electric vehicles may incorporate systems or components that enable regenerative braking, such as sensors, controllers, and electric brake actuators.

4. Space Optimization: Electric vehicles often have different packaging requirements compared to traditional internal combustion engine vehicles. The axles in electric vehicles are designed to accommodate the space constraints and specific layout of the vehicle, considering the placement of the battery pack, electric motor(s), and other components.

5. Weight Considerations: Electric vehicles strive to optimize weight distribution to enhance efficiency and handling. Axles in electric vehicles may be designed with lightweight materials or innovative construction techniques to minimize weight while maintaining structural integrity and durability.

It’s important to note that the specific design and characteristics of axles in electric vehicles can vary depending on the vehicle manufacturer, drivetrain configuration (e.g., front-wheel drive, rear-wheel drive, all-wheel drive), and other factors. Automotive manufacturers and suppliers continually innovate and develop new axle technologies to meet the evolving demands of electric vehicle propulsion systems.

Where can I purchase high-quality replacement axles for my make and model of vehicle?

When it comes to purchasing high-quality replacement axles for your specific make and model of vehicle, there are several reliable sources you can consider. Here are some options:

- Authorized Dealerships:

- Independent Auto Parts Stores:

- Online Retailers:

- Specialty Performance Retailers:

- Local Salvage Yards:

- Vehicle Manufacturer’s Online Parts Store:

Authorized dealerships of your vehicle’s manufacturer are a trustworthy option for purchasing replacement axles. They offer genuine parts that are specifically designed and engineered for your make and model. Contact your local dealership’s parts department to inquire about the availability of replacement axles.

Independent auto parts stores often carry a wide range of replacement axles from reputable manufacturers. These stores typically have knowledgeable staff who can help you identify the correct axle for your vehicle. Examples of popular auto parts stores include AutoZone, Advance Auto Parts, and O’Reilly Auto Parts.

Online retailers provide a convenient way to browse and purchase replacement axles from the comfort of your home. Websites such as Amazon, eBay, and RockAuto offer extensive selections of axles for various vehicle makes and models. Be sure to verify the compatibility of the axles with your specific vehicle before making a purchase.

If you are looking for high-performance or upgraded axles, specialty performance retailers may be the way to go. These retailers cater to enthusiasts and offer axles that are designed to handle increased power, torque, or off-road demands. Examples of specialty performance retailers include Summit Racing, Jegs, and 4 Wheel Parts.

Salvage yards, also known as junkyards or auto recyclers, can be a cost-effective option for finding used axles in good condition. Some salvage yards have an inventory system that allows you to search for specific parts based on your vehicle’s make and model. It’s important to thoroughly inspect used axles before purchase to ensure they meet your requirements.

Many vehicle manufacturers have their own online parts stores where you can directly purchase genuine replacement parts, including axles. These online stores provide the assurance of authenticity and compatibility with your specific make and model. Visit the official website of your vehicle’s manufacturer and look for their parts store section.

When purchasing replacement axles, it’s important to prioritize quality and ensure that the parts meet or exceed the original equipment specifications. Consider factors such as warranty coverage, customer reviews, and the reputation of the manufacturer or retailer. Additionally, consult with knowledgeable professionals or refer to your vehicle’s owner’s manual for specific axle specifications and recommendations.

How do solid axles differ from independent axles in terms of performance?

When comparing solid axles and independent axles in terms of performance, there are several key differences to consider. Both types of axles have their advantages and disadvantages, and their suitability depends on the specific application and desired performance characteristics. Here’s a comparison of solid axles and independent axles:

| Aspect | Solid Axles | Independent Axles |

|---|---|---|

| Load-Bearing Capability | Solid axles have high load-bearing capability due to their robust and sturdy construction. They can handle heavy loads and provide excellent stability, making them suitable for off-road vehicles, heavy-duty trucks, and towing applications. | Independent axles typically have lower load-bearing capability compared to solid axles. They are designed for lighter loads and offer improved ride comfort and handling characteristics. They are commonly used in passenger cars, sports cars, and vehicles with a focus on maneuverability and road performance. |

| Wheel Articulation | Solid axles have limited wheel articulation due to their connected and rigid design. This can result in reduced traction and compromised wheel contact with the ground on uneven terrain. However, solid axles provide excellent traction in situations where the weight distribution on all wheels needs to be maintained, such as in off-road or rock-crawling applications. | Independent axles offer greater wheel articulation as each wheel can move independently of the others. This allows the wheels to better conform to uneven terrain, maximizing traction and maintaining contact with the ground. Independent axles provide improved off-road capability, enhanced handling, and better ride comfort. |

| Ride Comfort | Due to their rigid design, solid axles generally provide a stiffer and less compliant ride compared to independent axles. They transmit more road shocks and vibrations to the vehicle’s occupants, resulting in a rougher ride quality. | Independent axles are known for providing better ride comfort. Each wheel can react independently to road imperfections, absorbing shocks and vibrations more effectively. This leads to a smoother and more comfortable ride, particularly on paved roads and surfaces with minor irregularities. |

| Handling and Stability | Solid axles offer excellent stability due to their connected nature. They provide better resistance to lateral forces, making them suitable for high-speed stability and towing applications. However, the rigid axle design can limit overall handling and maneuverability, particularly in tight corners or during quick direction changes. | Independent axles generally offer improved handling and maneuverability. Each wheel can react independently to steering inputs, allowing for better cornering performance and agility. Independent axles are commonly found in vehicles where precise handling and responsive steering are desired, such as sports cars and performance-oriented vehicles. |

| Maintenance and Repair | Solid axles are relatively simpler in design and have fewer moving parts, making them easier to maintain and repair. They are often more resistant to damage and require less frequent servicing. However, if a component within the axle assembly fails, the entire axle may need to be replaced. | Independent axles are typically more complex in design and have multiple moving parts, such as control arms, CV joints, or bearings. This complexity can result in higher maintenance and repair costs. However, if a failure occurs, only the affected component needs to be replaced, reducing repair expenses compared to replacing the entire axle. |

It’s important to note that advancements in suspension and axle technologies have resulted in various hybrid systems that combine features of solid and independent axles. These systems aim to provide a balance between load-bearing capability, wheel articulation, ride comfort, and handling performance based on specific application requirements.

In summary, solid axles excel in load-bearing capability, stability, and durability, making them suitable for heavy-duty applications and off-road conditions. Independent axles offer improved ride comfort, better wheel articulation, enhanced handling, and maneuverability, making them suitable for passenger cars and vehicles focused on road performance. The choice between solid axles and independent axles depends on the specific needs and priorities of the vehicle or machinery.

editor by CX 2024-04-09

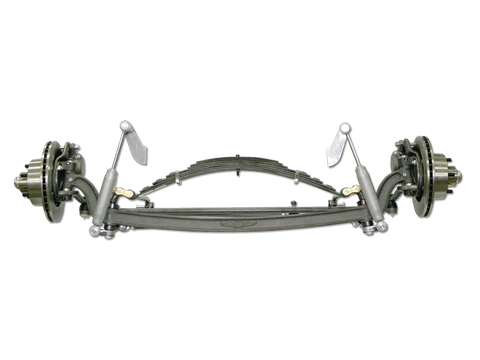

China Good quality 3500 Lbs Square Steel Beam Axle with Electric Brake or Hydraulic Brake bent axle

Product Description

Product Description

| Tubing: | 2 3/8″ OD (Standard), Galvanized Option (Marine),Corrosion Resistant Hubs |

| • V-Bend Beam Option | |

| Bolt Pattern Options: | • 5 on 4 1/2″, 4 3/4″, 5″, and 5 1/2″ |

| • 6 on 5 1/2″ | |

| Brake Options: | Some available with parking feature. |

| • 10″ x 2 1/4″ Electric (Manual or Nev-R-Adjust ) | |

| • 10″ x 2 1/4″ Hydraulic (Uni-Servo, Duo-Servo or | |

| Freebacking) | |

| • 10″ X 2 1/4″ Hydraulic Freebacking Corrosion | |

| Resistant (Galv/Marine Axle) | |

| • Hydraulic Disc: 5 on 4 1/2″ only | |

| Spindles: | Uses L68149 Inner Bearing, L44649 Outer Bearing. |

| • Straight • Drop: 4″ or 6″ | |

| • Stainless Steel Wear Sleeves on Galvanized Axles |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | One Year |

|---|---|

| Condition: | New |

| Axle Number: | 2 |

| Application: | Trailer |

| Certification: | ISO |

| Material: | Steel |

| Samples: |

US$ 170/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does a solid beam axle impact the ride quality of a vehicle?

A solid beam axle can have both positive and negative impacts on the ride quality of a vehicle. The specific effects depend on various factors, including the suspension setup, road conditions, and the vehicle’s intended use. Here’s how a solid beam axle influences ride quality:

1. Simplicity and Durability:

Positively, solid beam axles are known for their simplicity and durability. The absence of complex moving parts makes them robust and less prone to mechanical failures. This can contribute to a smoother ride over time, as there are fewer components to wear out or require maintenance.

2. Load Distribution:

A solid beam axle’s design allows for even distribution of weight across both wheels on the axle. This can lead to improved stability and handling, especially when carrying heavy loads. Vehicles with solid beam axles may have reduced body roll, enhancing the perception of ride quality.

3. Off-Road Capability:

Solid beam axles are commonly used in off-road vehicles due to their ability to maintain wheel contact with uneven terrain. In off-road applications, this feature can lead to a more comfortable ride, as the suspension flexes to absorb shocks and maintain traction on challenging surfaces.

4. Stiffness and Comfort:

On the downside, solid beam axles are generally stiffer compared to independent suspension systems. This stiffness can result in a less comfortable ride on smooth or well-paved roads. The vehicle may transmit more road imperfections and vibrations to the passengers.

5. Limited Articulation:

In certain situations, a solid beam axle’s limited articulation can impact ride quality. For example, when one wheel encounters a bump or obstacle, the other wheel is affected as well. This can lead to a bumpier ride compared to independent suspension systems, where each wheel can move independently to absorb shocks.

6. Road Conditions:

Ride quality is highly dependent on road conditions. On rough, uneven, or unpaved roads, a solid beam axle may perform better by maintaining wheel contact and stability. Conversely, on smooth and well-maintained roads, the ride quality may be less comfortable due to the stiffness of the axle.

7. Vehicle Design and Tuning:

Manufacturers can influence ride quality by designing the suspension components and tuning the shock absorbers to complement the solid beam axle. While the inherent stiffness remains, adjustments can be made to mitigate the negative effects and enhance comfort.

8. Passenger Expectations:

Ultimately, perceptions of ride quality can vary among passengers. Some may prioritize stability and load-carrying capacity, accepting the trade-off of a stiffer ride. Others may prioritize a smoother, more comfortable ride and opt for vehicles with independent suspension systems.

Summary:

The impact of a solid beam axle on ride quality is influenced by various factors, including the vehicle’s design, suspension tuning, and road conditions. While solid beam axles offer durability, load distribution, and off-road capability, they may result in a stiffer and less comfortable ride on smooth roads when compared to independent suspension systems.

Are there specific driving conditions or terrains where beam axles perform better?

Beam axles are well-suited for certain driving conditions and terrains where their design and characteristics provide advantages. Here are some situations where beam axles may perform better:

1. Off-Road and Rough Terrain:

Beam axles are highly effective in off-road and rough terrain environments. Their key advantages in such conditions include:

- Ground Clearance: Beam axles often provide good ground clearance, allowing vehicles to navigate over rocks, ruts, and uneven terrain without getting stuck.

- Wheel Articulation: Beam axles offer excellent wheel articulation, allowing the wheels to maintain contact with the ground even when the terrain is uneven. This enhances traction and stability.

- Durability: Off-road environments can be punishing, and beam axles are known for their durability and resistance to damage from impacts and obstacles.

2. Heavy-Duty and Commercial Vehicles:

Beam axles are commonly used in heavy-duty and commercial vehicles due to their load-bearing capacity and robustness. In such applications:

- Weight Distribution: Beam axles help distribute the weight of the vehicle and cargo evenly, which is critical for load-bearing and stability in applications like trucks and buses.

- Durability and Longevity: Commercial vehicles endure extensive use, so the durability of beam axles is advantageous for minimizing maintenance and downtime.

3. Simplified Maintenance:

Beam axles are relatively easy to maintain and repair, making them suitable for applications where accessibility to service and maintenance is essential. Simple designs can save time and resources in maintenance operations.

4. Classic and Vintage Cars:

Some classic and vintage vehicles use beam axles, and enthusiasts appreciate the authenticity and historical significance of these designs. While they may not be the most advanced suspension systems, they offer a unique driving experience.

5. Towing and Trailering:

Beam axles are often used in trailers and semi-trailers, providing support for the trailer’s weight and cargo. Their load-bearing capacity and simplicity make them suitable for these applications.

6. Custom Off-Roading and 4×4 Vehicles:

Enthusiasts and off-road hobbyists often modify their vehicles with beam axles to improve off-road performance. Lifted suspensions and enhanced articulation can make custom 4×4 vehicles better suited for challenging terrains.

Summary:

Beam axles excel in specific driving conditions and terrains, particularly in off-road, heavy-duty, and commercial applications. Their robustness, ground clearance, and durability are key attributes that make them perform better in these environments. However, in everyday passenger cars and modern vehicles, independent suspension systems are more common due to their comfort and handling advantages on paved roads.

What are the advantages and disadvantages of using a beam axle?

A beam axle, also known as a solid axle or live axle, has its own set of advantages and disadvantages, which can make it suitable or less suitable for various vehicle applications:

Advantages of Using a Beam Axle:

- 1. Durability: Beam axles are known for their robust construction and ability to withstand heavy loads and rough terrain. They are commonly used in applications where durability and strength are paramount, such as in heavy-duty trucks and off-road vehicles.

- 2. Cost-Effective: Beam axles are generally simpler and more cost-effective to manufacture and maintain compared to independent suspension systems. This makes them an economical choice for certain vehicle types.

- 3. Load-Carrying Capacity: Vehicles with beam axles have excellent load-carrying capacity, making them suitable for applications that involve transporting heavy goods or towing trailers.

- 4. Articulation (Off-Road): In off-road and 4×4 vehicles, front and rear beam axles provide exceptional articulation, allowing the wheels to maintain contact with uneven terrain, enhancing off-road performance.

- 5. Simplicity: The design of a beam axle is straightforward and lacks complex components, making it easier to maintain and repair.

Disadvantages of Using a Beam Axle:

- 1. Ride Comfort: Vehicles with beam axles often provide a less comfortable ride, especially on uneven road surfaces, as both wheels on the same axle move together in response to bumps and imperfections.

- 2. Reduced Traction: In off-road or slippery conditions, the lack of independent wheel movement can reduce traction, as one wheel’s loss of grip affects the other on the same axle.

- 3. Handling and Stability: Beam axles may result in less precise handling and stability, particularly in high-speed or cornering situations, compared to vehicles with independent suspension.

- 4. Weight: The solid construction of a beam axle can add weight to the vehicle, which can impact fuel efficiency and overall performance.

- 5. Limited Applications: Beam axles are less versatile and are typically used in specific applications, such as rear axles in trucks, off-road vehicles, and some industrial vehicles. They are less common in modern passenger cars due to their limitations in ride comfort and handling.

The choice of whether to use a beam axle or independent suspension depends on the intended use of the vehicle and the trade-offs between durability, load-carrying capacity, ride comfort, and handling characteristics.

editor by CX 2024-01-11

China 7,000 lb. Flexiride Adjustable Torsion Half Axles (with 8-6.5″ bolt circle hub and drum with 12″ hydraulic brakes full assembled) with Hot selling

Item Description

seven,000 lb. Flexiride Adjustable Torsion Fifty percent Axles (with 8-6.5″ bolt circle hub and drum with 12″ hydraulic brakes full assembled with backing plates, bearings, and seals mounted.)

| Element NO. | Ability | Bolt Sample | Bearing | Drum Diameter | Brake Sort |

| HTA005 | 7000 lbs | eight-6.5″ | one-3/4″(25580) 1-1/4″(14125A), 1-3/4″(25580) 2″(28580) |

twelve” x 2″ | twelve” hydraulic brake |

HangZhou CZPT Equipment Co., Ltd is a specialist manufacturer of trailer parts in HangZhou, ZHangZhoug Province, China considering that 2016.

We can make many trailer elements & components as follows: Towbars, axles, brake drums, hubs, brake disc, bearings, springs and springs and suspension kits, couplings, mudguards, U-Bolts, Jockey Wheels, keel rollers and brackets, wobble roller, wheel spacer, equalizers and all add-ons related to trailers.

If you can send out me the drawings or technical specs of the trailer areas, mechanical elements and wheels, we can give you our price.

Welcome to enquiry and email me,thanks!

Q1: Do you have factory?

A: Sure, we have our own factory, personal engineers, we can meet up with custom’s exclusive prerequisite.

Q2: Can I have a sample purchase?

A: Sure, welcome sample order to take a look at and verify quality. Blended samples are acceptable.

Q3: It is Okay to print my logo on your product?

A: Of course, we can according to your actual requirement.

This autumn:How do you ship the products and how long does it consider arrive?

A: We normally shipped by DHL, UPS, FedEx, it usually will take 3-5 times to get there. Airline and sea transport also optional.

Q5: What is your advantages?

A: We are expert provider for more than ten many years, we always place the quality and price at the first spot. At the very same time, our merchandise are exported to a variety of nations, we have total encounter to solve thorny problems.

1-Welcome OEM

- You can use your own brand names or ours, if you use our brand, our expert team will assist you style the packing.

two-Our services

- You inquiry relevant to our products or rates will be replied in 24 hrs.

- Nicely-trained and knowledgeable staffs to solution all your enquirys in fluent English.

- Security of your income area, concepts of your layout and all your personal details.

- We have a QC crew, every single product will be checked by them before packed.

three-Welcome to pay a visit to

- When you come to our organization go to us, we will organize a auto for choosing up and help you e-book hotel. If you want to check out the nearby scenic place, our colleague will accompany you.

four-Warranty

- Client must be offer the movie and the images for the difficulty merchandise.

- Goods returned inside the warranty period of time need to bear product variety & day code.

five-Right after services

- In manufacturing and right after supply, we will keep track of on time and notify you products predicament.

- When the items arrived, if you discover any layout and quality queries, or distinction from your samples, please come to feel free of charge to contact us, we will discover the question and remedy it with you.

|

US $330 / Set | |

10 Sets (Min. Order) |

###

| Condition: | New |

|---|---|

| Axle Number: | 2 |

| Application: | Trailer |

| Certification: | ASTM, CE, DIN, ISO |

| Material: | Steel |

| Type: | Rear Axles |

###

| Samples: |

US$ 330/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Part NO. | Capacity | Bolt Pattern | Bearing | Drum Diameter | Brake Type |

| HTA005 | 7000 lbs | 8-6.5" | 1-3/4"(25580) ; 1-1/4"(14125A), 1-3/4"(25580) ; 2"(28580) |

12" x 2" | 12" hydraulic brake |

|

US $330 / Set | |

10 Sets (Min. Order) |

###

| Condition: | New |

|---|---|

| Axle Number: | 2 |

| Application: | Trailer |

| Certification: | ASTM, CE, DIN, ISO |

| Material: | Steel |

| Type: | Rear Axles |

###

| Samples: |

US$ 330/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Part NO. | Capacity | Bolt Pattern | Bearing | Drum Diameter | Brake Type |

| HTA005 | 7000 lbs | 8-6.5" | 1-3/4"(25580) ; 1-1/4"(14125A), 1-3/4"(25580) ; 2"(28580) |

12" x 2" | 12" hydraulic brake |

What Is an Axle?

An axle is the central shaft of a vehicle that rotates a wheel or gear. It may be fixed to the wheels or to the vehicle itself, and can rotate with the wheels and gears. It may include bearings and mounting points. If the axle is fixed to the vehicle, it may have a steering or drive shaft attached.

Rear axle

The rear axle is a crucial part of your vehicle. If it fails to function correctly, it can cause major issues when driving at high speeds. This assembly can be a complicated component, and it is crucial that you find a mechanic who knows how to fix it. Rear axles require periodic gear oil replacement and bearing adjustments.

The rear axle is the final leg of the drivetrain, transferring rotational power from the driveshaft to the rear wheels. While the design of the rear axle varies between vehicles, all axles are designed to follow similar principles. Rear axles may have a single drive shaft or two. The drive shafts are mounted at either end of the axle.

The rear axle ratio is important because it affects how much fuel the truck uses. The lower the ratio, the more fuel-efficient the vehicle is. Higher numbers, like 4:10, are better for towing, but they will decrease fuel economy. When choosing a rear axle ratio, be sure to consider how much weight you’ll be hauling.

The rear axle is the most complicated part of the vehicle. It has many components and may not be easily visible. However, a properly functioning rear axle is essential for maximizing safety and performance. If you have a problem, you should contact a professional for a quick and easy fix. Even minor issues can make a significant difference in how your car or truck functions. A professional will ensure that your vehicle’s rear axle will be up to OEM standards.

Semi-floating axle

A semi-floating axle is the next step up from a stub axle. Semi-floating axles have a bearing that supports the shaft, which then floats inside the axle casing. These axles are best suited for midsize trucks. They are also lighter than full-floating axles and can be manufactured at a lower cost.

This design is most commonly found on rear-wheel-drive passenger cars and lighter trucks. The semi-floating design also allows for a wider diameter axle shaft, and it can increase axle capacity by increasing the diameter of the axle shaft. It also has a wider offset to accommodate larger tires. It can accommodate any offset, although this is usually only useful in off-road environments.

Semi-floating axles are often made with a tapered end. This helps keep the axel from twisting while providing traction. The rear hub of a semi-floating axle is usually connected to the axel via a big, strong nut. This nut also provides friction on the axel shaft.

A full-floating axle is common in 3/4-ton and 1/2-ton trucks. It is important to note, however, that almost all factory full-floating rear ends use eight-lug wheels. However, this rule is not strictly enforced and some companies, like Czpt, specialize in semi-floating axles and custom axles.

Drive shaft

A drive shaft is an important part of your vehicle’s drivetrain, which helps to transfer torque from the transmission to the drive wheels. You’ll need to know how it functions in order to properly maintain your car. Fortunately, there are a variety of different parts you can use to upgrade your drive shaft.

In order to improve the performance of your vehicle’s drivetrain, you can replace your existing drive shaft with an upgraded one. These are available in various lengths, so that you can find the right length and fit for your vehicle. Some shafts can even be customized to fit the exact length of your axle.

Generally, short axle shafts are made of solid steel. The longer ones are made of aluminum or carbon fiber. To ensure a smooth and safe ride, they are dynamically balanced to eliminate vibrations. Some models are fitted with giubo joints and universal joints to absorb shock. You can also add flex discs to improve your suspension and dampen the bucking sensation of a drive shaft.

You can tell if your drive shaft needs replacement if you hear a clicking noise while driving. This noise is often audible when the vehicle is turning sharply. You should take your vehicle to a mechanic as soon as you hear this noise, or it could lead to a costly repair. In addition to a clicking noise, your car may also be exhibiting a shuddering or vibrating sensation. If you’re experiencing any of these symptoms, you should take your car in for a checkup by an ASE certified technician. If you ignore these warnings, your car’s drive shaft could separate, causing you a lot of damage.

The drive shaft is attached to the axle flange by a drive shaft bolt. This is an important part of the drivetrain because it’s the only point where the drive shaft will connect to the axle. If the bolt is too long, it could be vulnerable to damage if the washers don’t fit tightly. The drive shaft socket yoke can also be easily damaged when you loosen the bolt.

U-joint

When you replace a u-joint on an axle, you need to take a few things into consideration. One of these considerations is the type of grease you’re going to use. Some of these greases are better than others, and you should always check for a quality grease before you install a new one. A good grease can help to reduce the friction and improve the temperature resistance of the part.

It’s also important to check the u-joint itself. This is the joint between the axle shaft and the wheel. If it’s not functioning properly, it could cause further problems. You should inspect the u-joint every time you change the oil in your vehicle. You can test its lubrication by pressing on the tire with a pry bar or axle stands. You can also try turning the steering wheel fully to test if the joint is loose.