Product Description

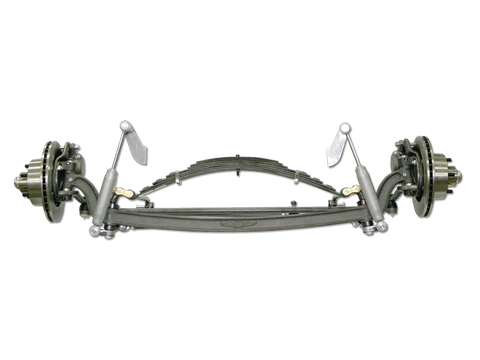

13ton 16ton American CZPT Type Square Beam Semi Trailer Axle for Sale

1.Company introduction:

ZheJiang CZPT Co., Ltd is 1 of the major manufacturers specializing in the production of trailer axles.

Our company has high technological background, sophisticated manufacturing technology, advances detection means, perfect quality assurance system. It is a specialized manufacturer integrating scientific research, design, production and sales.

The production of “FUSAI” trailer axles passed the national authoritative department detection. The fatigue life is up to 1,500,000 times without damage-more than 3 times above the national standard, which is in the leading domestic level, and reach or exceed the international standards. Our products are popular not only in domestic markets, but all over the world. Since the products are designed and optimized by computer, they have reasonable structure, good braking performance, high strength and rigidity, strong bearing capacity, long service life, good service, trusted by the users.

2.Characteristics:

1.Special heat-treat,low-alloy steel axle beam,it has the vitues of good synthetic performance,strong load ability and lower self weight.

2.High quality alloy solid inserted spindle,through wholy heat treatment,provide superior fatigue capability.

3.High performance premium non-asbestos brake linings,estend serbice life.

4.Easy for ABS installation.

5.Camshaft,matching with special seals,can ensure no entry of the grease into the brake drum,more safety.

6.New tight fit hub cap habe O rings,high property for sealing.

7.Grease lubricant is supplied by Mobil that lengthens the time of free maintenance.

8.Full range of stud fixing such as ISO,BSF and JAP,it can meet the requirements of various wheel rims.

3.Specification

| Axle Type | Bearings | Max. Capacity (T) |

Brake (mm) |

Track (mm) |

Center Distance Of Brake Chamber (mm) |

Axle Tube (mm) |

Stud |

PCD (mm) |

Hole Diameter (mm) |

Total Length (mm) |

Weight (kg) |

| FS- 2001 |

HM212049/10 HM218248/10 |

11 | 420*180 | 1850 | 410 | Φ127*16 | 10*M22*1.5ISO | 285.75 | 221 | 2185 | 363 |

| FS- 2002 |

HM212049/10 HM218248/10 |

11 | 420*180 | 1850 | 400 | Φ127*16 | 10*M20*1.5ISO | 335 | 281 | 2185 | 350 |

| FS- 2003 |

HM518445/10 HM518445/10 |

12 | 420*180 | 1820 | 368 | Φ127*16 127*127*16 |

10*M22*1.5ISO | 335 | 281 | 2165 | 361 |

| FS- 2004 |

HM518445/10 HM518445/10 |

12 | 420*180 | 1820 | 368 | Φ127*16 127*127*16 |

10*M20*1.5JIS | 285.75 | 221 | 2165 | 347 |

| FS- 2401 |

HM518445/10 HM518445/10 |

13 | 420*180 | 1840 | 388 | 150*150*12 | 10*M22*1.5ISO | 335 | 281 | 2185 | 363 |

| FS- 2402 |

HM518445/10 HM518445/10 |

13 | 420*180 | 1840 | 388 | 150*150*12 | 10*M20*1.5JIS | 285.75 | 221 | 2185 | 350 |

| FS- 2403 |

HM518445/10 HM518445/10 |

13 | 420*180 | 1840 | 388 | 150*150*12 | 8*M20*1.5JIS | 285 | 221 | 2185 | 365 |

| FS- 2404 |

HM518445/10 HM518445/10 |

16 | 420*220 | 1840 | 354 | 150*150*16 | 8*M22*1.5ISO | 335 | 281 | 2185 | 421 |

4.Scope of our business:

1.axles (German type axle, American type axle, Spoke axle, Axle without brake)

2.Suspension (Bogie suspension, Spoke suspension, Mechanical suspension)

3.Landing gear (Outboard or inboard)

4.Fifth wheel (2” 3.5”)

5.King pin (2” 3.5”)

6.Other axles and related parts (Low bed axle, hub, rims, spring, drum…)

Any question, contact Claire /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Available |

|---|---|

| Warranty: | 1 Year |

| Type: | Axle |

| Certification: | ISO/TS16949, CCC, DOT, ISO, CE |

| Loading Weight: | 13 Ton 16 Ton |

| ABS: | Optional |

| Customization: |

Available

| Customized Request |

|---|

Can you provide examples of classic and vintage vehicles that use beam axles?

Classic and vintage vehicles often featured beam axles in their suspension systems. These axles were widely used in the past and can still be found in iconic automobiles. Here are some examples of classic and vintage vehicles that used beam axles:

1. Ford Model T (1908-1927):

The Ford Model T, also known as the “Tin Lizzie,” is a classic example of an early automobile that used a beam axle. It was one of the first mass-produced cars and played a significant role in making automobiles accessible to the masses. The Model T’s simple and robust suspension design included a beam axle.

2. Willys Jeep (1941-1986):

The Willys Jeep, originally designed for military use during World War II, became an iconic vehicle with civilian versions. Jeeps are known for their off-road capabilities, and many early models featured beam axles in both the front and rear suspensions.

3. Volkswagen Beetle (1938-2003):

The Volkswagen Beetle, often called the “Bug,” is one of the most recognizable and beloved classic cars. Many early models, including the original air-cooled Beetles, used beam axles in the rear suspension. The suspension design contributed to the Beetle’s simple and reliable characteristics.

4. Chevrolet Advance Design Trucks (1947-1955):

Chevrolet’s Advance Design trucks, also known as the “Task Force” trucks, featured beam axles in their suspensions. These trucks were popular for both commercial and civilian use and are considered classic American pickups.

5. Citroën 2CV (1948-1990):

The Citroën 2CV, also known as the “Deux Chevaux,” is a classic French car known for its unconventional design. The 2CV’s suspension included a beam axle in the rear, which contributed to its ability to handle rough roads and challenging conditions.

6. Land Rover Series (1948-1985):

The Land Rover Series, especially the early models, featured beam axles in their suspension systems. Land Rovers are renowned for their off-road capabilities and are often associated with exploration and adventure.

7. Dodge Power Wagon (1945-present):

The Dodge Power Wagon is a classic American pickup truck with a history dating back to World War II. Early models of the Power Wagon used beam axles in the front and rear suspensions, making them capable off-road and workhorse vehicles.

8. Morris Minor (1948-1971):

The Morris Minor is a classic British car with a reputation for practicality and reliability. Many early models of the Morris Minor featured beam axles in their suspensions, contributing to the car’s durability.

Summary:

Classic and vintage vehicles from different parts of the world used beam axles in their suspension systems. These examples showcase the historical significance and enduring appeal of cars and trucks with beam axles, which were celebrated for their simplicity and durability.

How do beam axles contribute to the load-carrying capacity of vehicles?

Beam axles play a crucial role in enhancing the load-carrying capacity of vehicles, especially in heavy-duty and commercial applications. Their design and characteristics contribute to this capacity in several ways:

1. Weight Distribution:

Beam axles are known for their ability to evenly distribute the weight of the vehicle and its cargo. This even distribution of weight helps maintain stability and balance, preventing overloading of a specific wheel or axle. In heavy-duty trucks and buses, this balanced weight distribution is vital to ensure safe and efficient transportation of goods and passengers.

2. Load-Bearing Capacity:

Beam axles are engineered to handle heavy loads. Their robust construction and materials are chosen to withstand the stress and weight of cargo. This load-bearing capacity is critical for commercial vehicles that carry substantial payloads, such as delivery trucks, construction vehicles, and agricultural equipment.

3. Durability and Resistance:

Heavy-duty and commercial vehicles are exposed to challenging conditions and road surfaces. Beam axles are designed to be durable and resistant to damage from road impacts, rough terrain, and heavy loads. This durability ensures that the axles can maintain their load-carrying capability over time, reducing the need for frequent maintenance or repairs.

4. Support for Trailers:

Beam axles are commonly used in trailers and semi-trailers, where they provide support for the weight of the trailer and its cargo. This support is essential for maintaining stability and preventing issues like trailer sway. The load-bearing capacity of beam axles is instrumental in safely transporting goods and materials on the road.

5. Simplicity and Maintenance:

The straightforward design of beam axles simplifies maintenance and reduces downtime. This is particularly important in commercial applications where minimizing maintenance and maximizing uptime are priorities. The ease of maintenance helps ensure that the axles continue to contribute to the load-carrying capacity of the vehicle throughout their service life.

6. Customization:

In some cases, heavy-duty vehicles with beam axles can be customized to accommodate specific cargo and load requirements. This may involve adjusting the suspension components and optimizing the vehicle’s load-carrying capability based on the intended use.

Summary:

Beam axles are a fundamental component in enhancing the load-carrying capacity of vehicles, particularly in heavy-duty and commercial applications. Their ability to distribute weight evenly, handle heavy loads, resist damage, and simplify maintenance contributes to the overall efficiency and effectiveness of these vehicles in transporting goods, passengers, and cargo.

How does a solid beam axle work in the suspension of a vehicle?

A solid beam axle, also known as a live axle, is a type of suspension system commonly used in various vehicles. It operates differently from independent suspension systems, and its function can vary depending on whether it’s used as a rear axle or front axle in a vehicle:

Rear Solid Beam Axle:

In vehicles with rear solid beam axles, the following key characteristics define how they work in the suspension:

- Single Solid Axle: A solid beam axle is a single, rigid axle that spans the width of the vehicle. It connects both rear wheels and is a single, solid unit.

- Equal Wheel Movement: When one wheel on the axle encounters a bump or road imperfection, the other wheel on the same axle is affected. Both wheels move up and down together, and this movement is linked by the axle.

- Simple and Robust: Solid beam axles are known for their simplicity and robustness. They can handle heavy loads and provide durability, making them suitable for applications like trucks, SUVs, and some off-road vehicles.

Front Solid Beam Axle:

Front solid beam axles are less common in modern vehicles but are used in some specific applications. Their operation is as follows:

- Single Solid Axle: Like the rear version, the front solid beam axle is a single, solid axle spanning the width of the vehicle.

- Equal Wheel Movement: The front solid beam axle connects both front wheels. When one wheel encounters an obstacle, both front wheels move up and down together, as they are linked by the axle.

- Off-Road Performance: Front solid beam axles are often used in off-road and 4×4 vehicles because they provide excellent articulation and durability, making them suitable for rugged terrain.

The key aspect of solid beam axles is that they do not allow independent movement of the wheels on the same axle. This means that when one wheel encounters an obstacle, the other wheel is affected as well. While this setup can provide robustness and load-carrying capacity, it may result in a less comfortable ride and reduced traction on uneven surfaces compared to vehicles with independent suspension.

It’s important to note that the choice between solid beam axles and independent suspension depends on the vehicle’s intended use, design goals, and the trade-off between load-carrying capacity and ride quality.

editor by CX 2024-01-23