Product Description

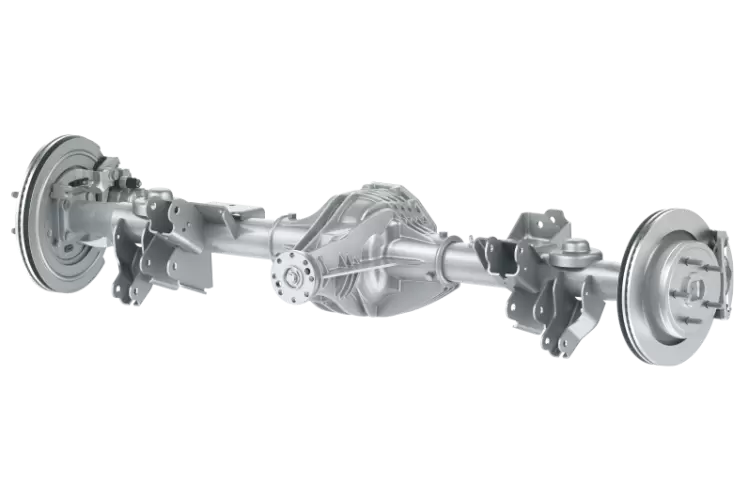

11ton 13ton Trailer Round Beam Axle with ABS

Company introduction:

ZheJiang CZPT Co.,Ltd is 1 of the major manufacturers specializing in the production of trailer axles.

Our company has high technological background, sophisticated manufacturing technology, advances detection means, perfect quality assurance system. It is a specialized manufacturer integrating scientific research, design, production and sales.

The production of “FUSAI” trailer axles passed the national authoritative department detection. The fatigue life is up to 1,500,000 times without damage-more than 3 times above the national standard, which is in the leading domestic level, and reach or exceed the international standards. Our products are popular not only in domestic markets, but all over the world. Since the products are designed and optimized by computer, they have reasonable structure, good braking performance, high strength and rigidity, strong bearing capacity, long service life, good service, trusted by the users.

“FUSAI” brand Fuwa style trailer axle

1.CZPT spindle design which is the widely used in the industry with proven performance

2.Low-alloy machined spindles, friction welded seamlessly, and overall heat treating process

3.Axle stubs and brake hubs are all CZPT forging, ensure they are more powerful and better steady

4.Special clone-shape design on the axle-shoulders, lessening stress concentration and enhancing anti-fatigue performance

5.Unique design on axle stubs (with a precise declination angel at both ends) to minimize tire wear

6.National and industry standard compliant set components

7.National Automobile Monitor and Inspection Center certified axle shaft that undergoes over 1.2 million times of Fatigue testing and built to meet or exceed national industry standards.

Specifications:

| Axle Type | Bearings | Max. Capacity (T) |

Brake (mm) |

Track (mm) |

Center Distance Of Brake Chamber (mm) |

Axle Tube (mm) |

Stud |

PCD (mm) |

Hole Diameter (mm) |

Total Length (mm) |

Weight (kg) |

| FS- 2001 |

HM212049/10 HM218248/10 |

11 | 420*180 | 1850 | 410 | Φ127*16 | 10*M22*1.5ISO | 285.75 | 221 | 2185 | 363 |

| FS- 2002 |

HM212049/10 HM218248/10 |

11 | 420*180 | 1850 | 400 | Φ127*16 | 10*M20*1.5ISO | 335 | 281 | 2185 | 350 |

| FS- 2003 |

HM518445/10 HM518445/10 |

12 | 420*180 | 1820 | 368 | Φ127*16 127*127*16 |

10*M22*1.5ISO | 335 | 281 | 2165 | 361 |

| FS- 2004 |

HM518445/10 HM518445/10 |

12 | 420*180 | 1820 | 368 | Φ127*16 127*127*16 |

10*M20*1.5JIS | 285.75 | 221 | 2165 | 347 |

| FS- 2401 |

HM518445/10 HM518445/10 |

13 | 420*180 | 1840 | 388 | 150*150*12 | 10*M22*1.5ISO | 335 | 281 | 2185 | 363 |

| FS- 2402 |

HM518445/10 HM518445/10 |

13 | 420*180 | 1840 | 388 | 150*150*12 | 10*M20*1.5JIS | 285.75 | 221 | 2185 | 350 |

| FS- 2403 |

HM518445/10 HM518445/10 |

13 | 420*180 | 1840 | 388 | 150*150*12 | 8*M20*1.5JIS | 285 | 221 | 2185 | 365 |

| FS- 2404 |

HM518445/10 HM518445/10 |

16 | 420*220 | 1840 | 354 | 150*150*16 | 8*M22*1.5ISO | 335 | 281 | 2185 | 421 |

Attention:

1. Optional track length available.

2. Optional ABS and automatic slack adjuster available.

3. All the components are in common use of Fuwa.

4. Rights of changing product’s design and specification are reserved.

More products and information, please refer to our website: sdfhcq

ZheJiang CZPT Co.,Ltd

Sales manager: Norton Hu

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Available |

|---|---|

| Warranty: | 1 Year |

| Type: | Axle |

| Certification: | ISO/TS16949, CCC, DOT, ISO, CE |

| Loading Weight: | 13ton |

| ABS: | With ABS |

| Customization: |

Available

| Customized Request |

|---|

Are there potential challenges or limitations to using beam axles in vehicles?

Using beam axles in vehicles has both advantages and disadvantages. It’s important to consider the challenges and limitations associated with beam axles:

1. Ride Quality:

Beam axles are generally stiffer than independent suspension systems. This stiffness can lead to a less comfortable ride on smooth or well-paved roads, as they transmit more road imperfections and vibrations to the passengers. Passengers may perceive this as a limitation in terms of ride comfort.

2. Limited Articulation:

Beam axles have limited articulation. When one wheel encounters a bump or obstacle, the other wheel is affected as well. This can result in a bumpier ride compared to independent suspension systems, where each wheel can move independently to absorb shocks. Off-road vehicles may experience challenges in maintaining traction on rough terrains due to this limitation.

3. Reduced Traction in Some Scenarios:

Beam axles can experience reduced traction in certain scenarios, such as when one wheel loses contact with the ground. In off-road situations, this can limit the vehicle’s ability to traverse uneven terrain, especially when compared to independent suspension systems that allow each wheel to react independently to ground conditions.

4. Challenging Maneuverability:

Maneuverability can be a limitation in vehicles with beam axles. The stiffness and design of beam axles can make it harder to navigate tight spaces or execute sharp turns. This can be a drawback, especially in urban environments or when parking in confined areas.

5. Weight Distribution:

Proper weight distribution is crucial for vehicle stability. Beam axles, while offering even weight distribution between wheels on the same axle, may not provide the same level of precision in weight distribution as independent suspension systems. This can affect handling and stability in some situations.

6. Limited Ride Comfort on Smooth Roads:

On smooth and well-paved roads, solid beam axles may lead to reduced ride comfort due to their stiffness. Passengers may experience a more jarring ride, and the vehicle may struggle to absorb minor road imperfections.

7. Noise and Vibration:

Beam axles can transmit more noise and vibration from the road to the vehicle’s occupants. This can result in a less refined and quieter cabin environment compared to vehicles with independent suspension systems.

8. Suspension Tuning Challenges:

Designing the suspension components and tuning the shock absorbers for vehicles with beam axles can be challenging. Manufacturers must strike a balance between load-carrying capacity and ride comfort. Achieving an ideal balance can be difficult and may require compromises.

9. Vehicle-Specific Considerations:

The limitations of beam axles can vary depending on the vehicle’s intended use and design. While some limitations may be acceptable in off-road or heavy-duty applications, they may not be suitable for passenger cars or vehicles designed for urban commuting.

Summary:

Beam axles offer advantages in terms of durability and load distribution, but they also come with limitations related to ride comfort, maneuverability, and traction in certain scenarios. Vehicle manufacturers must carefully consider these limitations and weigh them against the specific needs and intended use of the vehicle.

Can you describe the maintenance and repair considerations for beam axles?

Maintenance and repair of beam axles, also known as solid axles or live axles, are essential to ensure the longevity and proper functioning of a vehicle. Here are some key maintenance and repair considerations:

Maintenance:

- 1. Lubrication: Regularly inspect and lubricate the axle’s components, such as the bearings, bushings, and kingpins. Proper lubrication helps reduce friction and wear.

- 2. Inspection: Periodically inspect the axle for signs of damage, wear, or corrosion. Check for leaks from the axle’s seals and inspect the axle housing for cracks or dents.

- 3. Tire Alignment: Proper tire alignment is crucial to prevent uneven tire wear and maintain vehicle stability. Ensure that the wheels are aligned correctly to minimize stress on the axle components.

- 4. Wheel Balancing: Imbalanced wheels can cause vibrations and additional stress on the axle. Regularly balance the wheels to prevent premature wear of axle components.

- 5. Tightening Fasteners: Check and tighten fasteners, such as U-bolts and mounting brackets, to ensure they are secure and prevent axle misalignment.

Repair:

- 1. Bearing Replacement: If you notice excessive play, noise, or vibrations in the wheel, it may be a sign of bearing wear. Bearings should be replaced promptly to prevent further damage to the axle.

- 2. Seals and Gaskets: Leaking seals and gaskets should be replaced to prevent oil or grease loss and maintain proper lubrication of axle components.

- 3. Bushings and Kingpins: Worn or damaged bushings and kingpins can affect steering and handling. Replacement may be necessary to restore proper function.

- 4. Axle Straightening: In cases of minor axle damage or bending, some axles can be straightened and repaired. However, severe damage may require axle replacement.

- 5. Welding and Fabrication: In the event of cracks or structural damage to the axle housing, welding and fabrication may be required. This should be performed by a skilled professional to ensure the axle’s integrity.

- 6. Alignment: Proper alignment is critical to prevent uneven tire wear and handling issues. If the axle is misaligned, it should be realigned by a professional technician.

It’s important to note that the complexity of maintenance and repair tasks may vary depending on the type of vehicle and the specific design of the beam axle. Additionally, regular inspections and maintenance can help detect issues early, preventing more extensive and costly repairs in the long run. When performing maintenance and repairs on beam axles, it’s recommended to consult the vehicle’s service manual and seek assistance from qualified mechanics when needed.

What is a beam axle, and how does it differ from independent suspension?

A beam axle, also known as a solid axle or live axle, is a type of suspension system used in vehicles. It differs from independent suspension in several ways:

Beam Axle:

- A beam axle consists of a single solid beam (shaft) that spans the width of the vehicle and connects both wheels on the same axle. It is a single rigid unit.

- Beam axles are commonly found in older vehicles and some heavy-duty trucks and off-road vehicles.

- When one wheel encounters a bump or obstacle, the other wheel on the same axle is affected. This can result in a less comfortable ride and reduced traction for both wheels.

- Beam axles are generally more robust and suitable for heavy loads, making them preferred in certain commercial and industrial applications.

- They are relatively simple in design and tend to be more cost-effective to manufacture and maintain.

Independent Suspension:

- Independent suspension, on the other hand, allows each wheel to move independently of the other. It consists of separate suspension units for each wheel.

- Independent suspension is commonly used in modern passenger cars, SUVs, and performance vehicles.

- Each wheel responds individually to road imperfections, providing a smoother and more comfortable ride. It also improves traction, handling, and stability.

- Independent suspension is generally lighter and offers better handling characteristics, making it suitable for most everyday driving situations.

- However, it can be more complex and costly to manufacture and maintain compared to beam axles.

While beam axles are known for their strength and simplicity, independent suspension systems are favored for their superior ride comfort, handling, and adaptability to various road conditions. The choice between the two depends on the vehicle’s intended use, design goals, and the trade-off between load-carrying capacity and ride quality.

editor by CX 2024-02-08