Product Description

Product Description

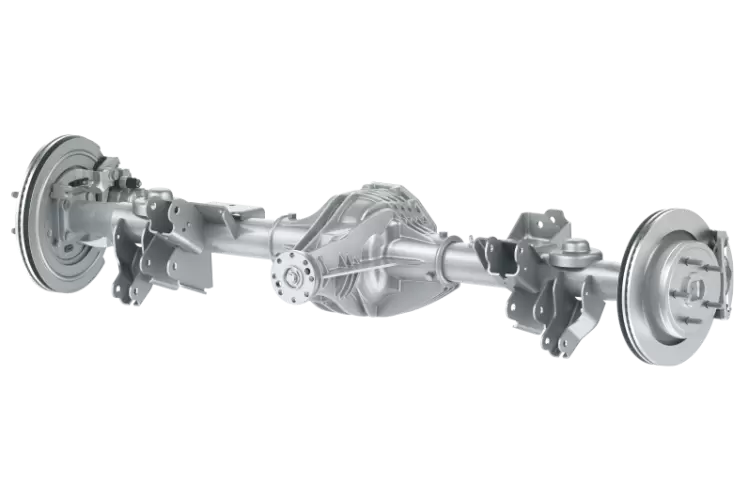

Our trailer axles are suitable for American and German trucks. We have many models. We can produce American & German Axles of various specifications according to your drawings, sample or specific parameters you give us.

|

Product Name |

Trailer Axle |

|

Type |

American drum type |

|

Capacity |

13T, 15T, 16T, 20T |

|

Total Length |

About 2185 mm (According to the model) |

|

Weight |

About 330 KG (According to the model) |

|

Material |

Iron |

|

Color |

Black |

|

Brand |

CCQ |

|

Package |

Carton, wooden box |

|

Quality |

Super |

|

Port |

China Port |

|

Payment |

T/T, L/C, D/P, D/A, MoneyGram, Credit Card, PayPal, Western Union |

|

Service |

OEM, ODM |

Accessories

It adopts high-quality accessories from major brands at home and abroad, and global standard American

axle specifications. It has strong practicability, low price and convenient maintenance.

Axle

The factory produces its own shaft tube with quality assurance and cost advantage. The assembly process

strictly abides by international quality standards to create high-quality products.

Trailer parts trailer axle performance:

1. Integrated high quality low-alloy axle tube has strong carrying capacity and high bending strength.

2. The axle tube tempered as a whole and then quenching optimized which made by finishing high-precision machinery.

3. Environmentally friendly Non-asbestos brake shoe which increase the wearing life more than 25%.

4. Brake components have strong interchangeability, S-camshaft, so that have more flexible and reliable brake action.

5. Adopt Mobil XHP222 grease which has maintenance-free longer.

6. Adopt heavy-duty bearings which specially used for heavy vehicles have strong interchangeability.

7. The unique beauty with O-ring of the steel wheel cover has special good performance.

8. ABS optional.

Recommended Products

Company Profile

We are 1 of a professional companies to develop and manufacture kinds of semi trailers. Our advantages are high quality with reasonable price. We have the largest trailer industrial park in Xihu (West Lake) Dis., the preferred key project in ZheJiang Province, and the ZheJiang provincial manufacturing demonstration platform.

Covering an area of more than 400 acres, the designed production capacity of the first phase is 30,000+ sets of semi-trailers, mainly focusing on flatbed semi-trailers and rear dump semi-trailers, Construction of 120,000 square meters of workshops, offices and living facilities, 4 special vehicle production lines, 3 painting lines, and 2 assembly lines have been completed and put into production.

Our attitude towards light-weighting: we do not oppose light-weighting, but reject blindly light-weighting.On the basis of ensuring the safety and firmness of the vehicle, lightweight processing must be done.Our philosophy was to create “More Resistant” semi-trailers. Company special vehicles are identified as ” ZheJiang famous product”.

We have many commercial partners in the Russian, Far East and Africa, Sales and service network are built through cooperation and franchise in Moscow, Novosibrisk, red culture, Harper, Vladivostok, Congo, Sultan. Which can satisfy the clients in Africa and Russia, ZheJiang Open CZPT Heavy Industry Co.,Ltd. is committed to provide modern transportation equipment and services, and dedicated to be responsible enterprise, the highest development, conscientious work, we hope to gain customer’s trust and become famous brand. We sincerely cooperate with customers at home and abroad.

Packaging & Shipping

FAQ

1. How is the quality of your products?

Our products are manufactured in strict accordance with national and international standards, and we test each product before delivery. If you would like to view our quality certification and various test reports, please contact us.

2. How about price?

We are a factory and CZPT to give you the lowest price. Please trust the quotation we would give you, and it is professional one.

3. Why should you chose us?

Choosing us happens because of quality, then price, and we can give you both. Additionally, we can also offer professional products inquiry,products knowledge train(for agents), smooth goods delivery, excellent customer solution proposals.

4. How to ensure the interests of buyers?

Our company supports Alibaba online trading, which not only ensures the safety of the buyer’s funds, but also guarantees the quality of the goods. From the outbound, to the loading, and finally to the receiving, the whole process is transparent.

5. How to guarantee delivery time?

We are a factory with a large inventory of stock, which guarantees that the goods will be shipped within the shortest time from the date of signing the contract.

6. How to get samples?

We can provide samples for buyer’s testing free of charge, but buyers need to pay for shipping costs.

| After-sales Service: | 2 Year |

|---|---|

| Condition: | New |

| Axle Number: | 2/3/4 Axles |

| Application: | Trailer |

| Certification: | ASTM, CE, ISO |

| Material: | Steel |

| Customization: |

Available

| Customized Request |

|---|

What innovations or advancements have been made in beam axle technology?

Beam axle technology, while known for its simplicity and durability, has seen innovations and advancements over the years to improve performance and versatility. Some notable developments in beam axle technology include:

1. Air Suspension:

One significant advancement is the integration of air suspension systems with beam axles. Air suspension allows for adjustable ride height and load-leveling capabilities, enhancing ride comfort and load-carrying capacity. This innovation is particularly valuable for commercial vehicles.

2. Steering Mechanisms:

Modern beam axles in some vehicles incorporate advanced steering mechanisms to improve maneuverability. Examples include rack-and-pinion steering or electronic power steering, which enhances control and handling, especially in heavy-duty and off-road applications.

3. High-Strength Materials:

Advancements in materials have led to the use of high-strength alloys and composite materials in beam axle construction. These materials offer improved strength-to-weight ratios, reducing overall weight while maintaining durability. Lighter axles contribute to better fuel efficiency in vehicles.

4. Redesigned Suspension Geometry:

Manufacturers have optimized the suspension geometry in some beam axle configurations to reduce vibration, enhance stability, and provide better handling. These improvements result in a more comfortable and controlled ride for both passengers and drivers.

5. Improved Lubrication Systems:

Better lubrication systems have been developed to ensure smoother operation and extended axle component lifespan. These systems help prevent wear and reduce maintenance requirements.

6. Enhanced Load-Carrying Capacity:

Advancements in axle design and materials have allowed for increased load-carrying capacity without compromising axle integrity. This is crucial for commercial vehicles that transport heavy loads.

7. Adaptive Damping Systems:

Some vehicles equipped with beam axles feature adaptive damping systems that adjust shock absorber settings in real-time based on road conditions and driving dynamics. This results in a smoother and more controlled ride, especially when the vehicle is fully loaded.

8. Noise and Vibration Reduction:

Manufacturers have focused on reducing noise and vibration in vehicles with beam axles. Improved bushings, dampers, and mounting systems help minimize unwanted noise and vibration, contributing to a quieter and more comfortable driving experience.

9. Maintenance and Diagnostic Technology:

Advancements in diagnostics and monitoring technology allow for proactive maintenance of beam axles. Sensor systems can detect issues early, improving safety and reducing unplanned downtime for maintenance and repairs.

Summary:

Beam axle technology has evolved to meet the changing demands of modern vehicles. These innovations enhance ride comfort, safety, load-carrying capacity, and overall performance, making beam axles a competitive choice for a wide range of applications, including commercial vehicles and off-road machines.

How does a live axle differ from a dead axle in the context of beam axles?

In the context of beam axles, live axles and dead axles represent two distinct configurations that serve different purposes and have specific characteristics:

Live Axle (Driven Axle):

A live axle is an axle that is actively connected to the engine and is responsible for driving the wheels. In a live axle configuration:

- The axle shafts are connected to the wheels and are capable of delivering power to propel the vehicle.

- The wheels on a live axle are actively powered and provide propulsion, typically in rear-wheel-drive or four-wheel-drive (4WD) vehicles.

- Live axles are common in trucks, off-road vehicles, and 4×4 vehicles, where the ability to provide power to multiple wheels is crucial for traction in challenging terrain.

- Live axles are sometimes referred to as “driven axles” because they actively drive the vehicle.

Dead Axle (Trailing or Support Axle):

A dead axle, in contrast, is an axle that is not powered and does not contribute to the vehicle’s propulsion. In a dead axle configuration:

- The axle shafts are not connected to the engine and do not receive power; they simply support the wheels.

- Dead axles are often used in the front of front-wheel-drive vehicles, where the engine provides power to the front wheels, and the rear wheels are supported by dead axles.

- These axles are also used in trailers and semi-trailers, where they support the weight of the trailer but do not provide power to the wheels.

- Dead axles are sometimes referred to as “trailing axles” or “support axles” because they do not actively drive the vehicle.

Differences:

The primary difference between live axles and dead axles in the context of beam axles is whether they are responsible for providing power to the wheels. Live axles actively drive the vehicle, while dead axles are passive and serve a support or trailing role. The choice between these configurations depends on the specific vehicle design and its intended use, with live axles favored for off-road and high-traction applications and dead axles used for support and weight distribution.

What are the advantages and disadvantages of using a beam axle?

A beam axle, also known as a solid axle or live axle, has its own set of advantages and disadvantages, which can make it suitable or less suitable for various vehicle applications:

Advantages of Using a Beam Axle:

- 1. Durability: Beam axles are known for their robust construction and ability to withstand heavy loads and rough terrain. They are commonly used in applications where durability and strength are paramount, such as in heavy-duty trucks and off-road vehicles.

- 2. Cost-Effective: Beam axles are generally simpler and more cost-effective to manufacture and maintain compared to independent suspension systems. This makes them an economical choice for certain vehicle types.

- 3. Load-Carrying Capacity: Vehicles with beam axles have excellent load-carrying capacity, making them suitable for applications that involve transporting heavy goods or towing trailers.

- 4. Articulation (Off-Road): In off-road and 4×4 vehicles, front and rear beam axles provide exceptional articulation, allowing the wheels to maintain contact with uneven terrain, enhancing off-road performance.

- 5. Simplicity: The design of a beam axle is straightforward and lacks complex components, making it easier to maintain and repair.

Disadvantages of Using a Beam Axle:

- 1. Ride Comfort: Vehicles with beam axles often provide a less comfortable ride, especially on uneven road surfaces, as both wheels on the same axle move together in response to bumps and imperfections.

- 2. Reduced Traction: In off-road or slippery conditions, the lack of independent wheel movement can reduce traction, as one wheel’s loss of grip affects the other on the same axle.

- 3. Handling and Stability: Beam axles may result in less precise handling and stability, particularly in high-speed or cornering situations, compared to vehicles with independent suspension.

- 4. Weight: The solid construction of a beam axle can add weight to the vehicle, which can impact fuel efficiency and overall performance.

- 5. Limited Applications: Beam axles are less versatile and are typically used in specific applications, such as rear axles in trucks, off-road vehicles, and some industrial vehicles. They are less common in modern passenger cars due to their limitations in ride comfort and handling.

The choice of whether to use a beam axle or independent suspension depends on the intended use of the vehicle and the trade-offs between durability, load-carrying capacity, ride comfort, and handling characteristics.

editor by CX 2023-11-10